Search By Year, Make and Model

Shop by Part Type

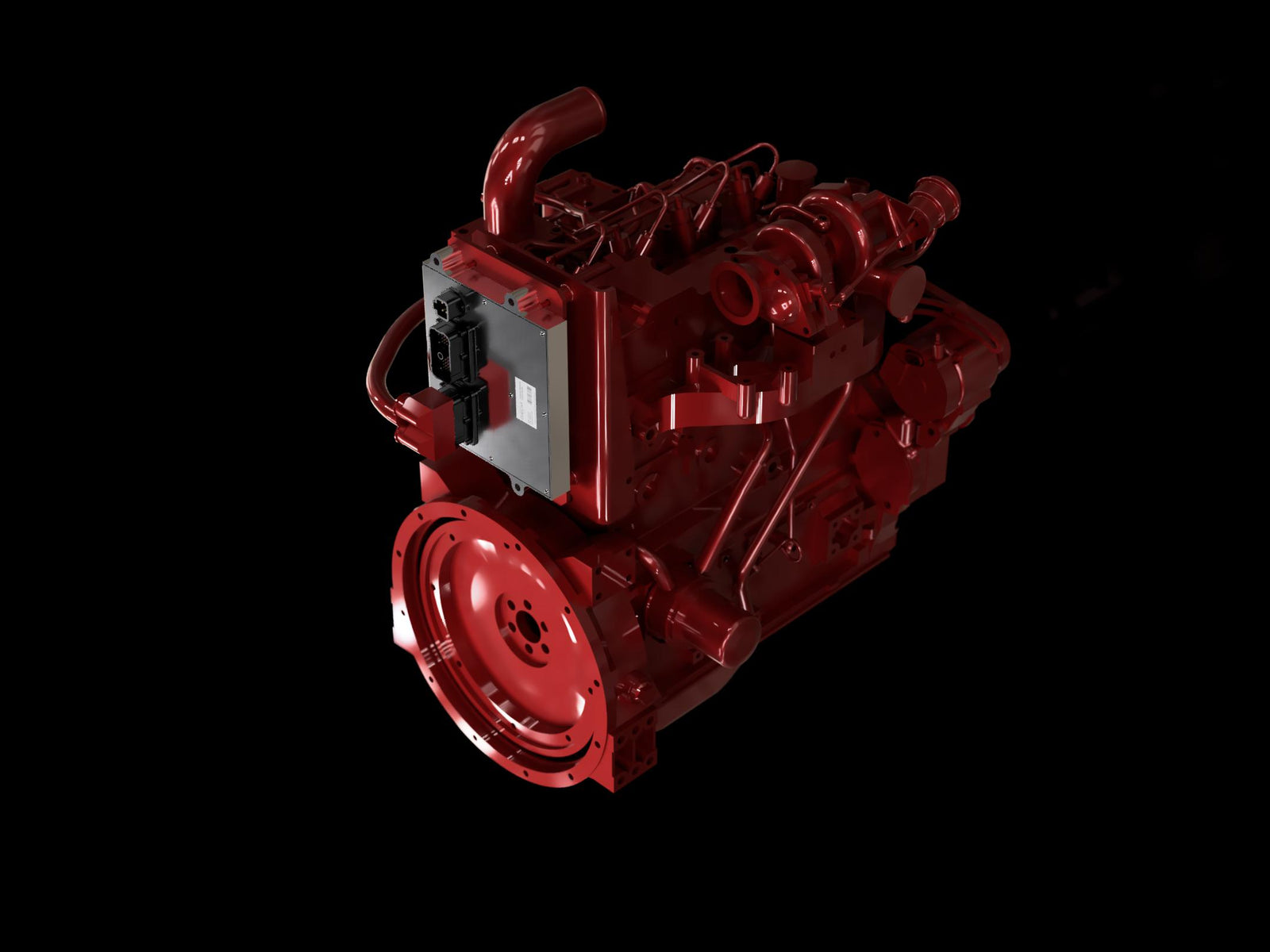

Welcome to GoECM

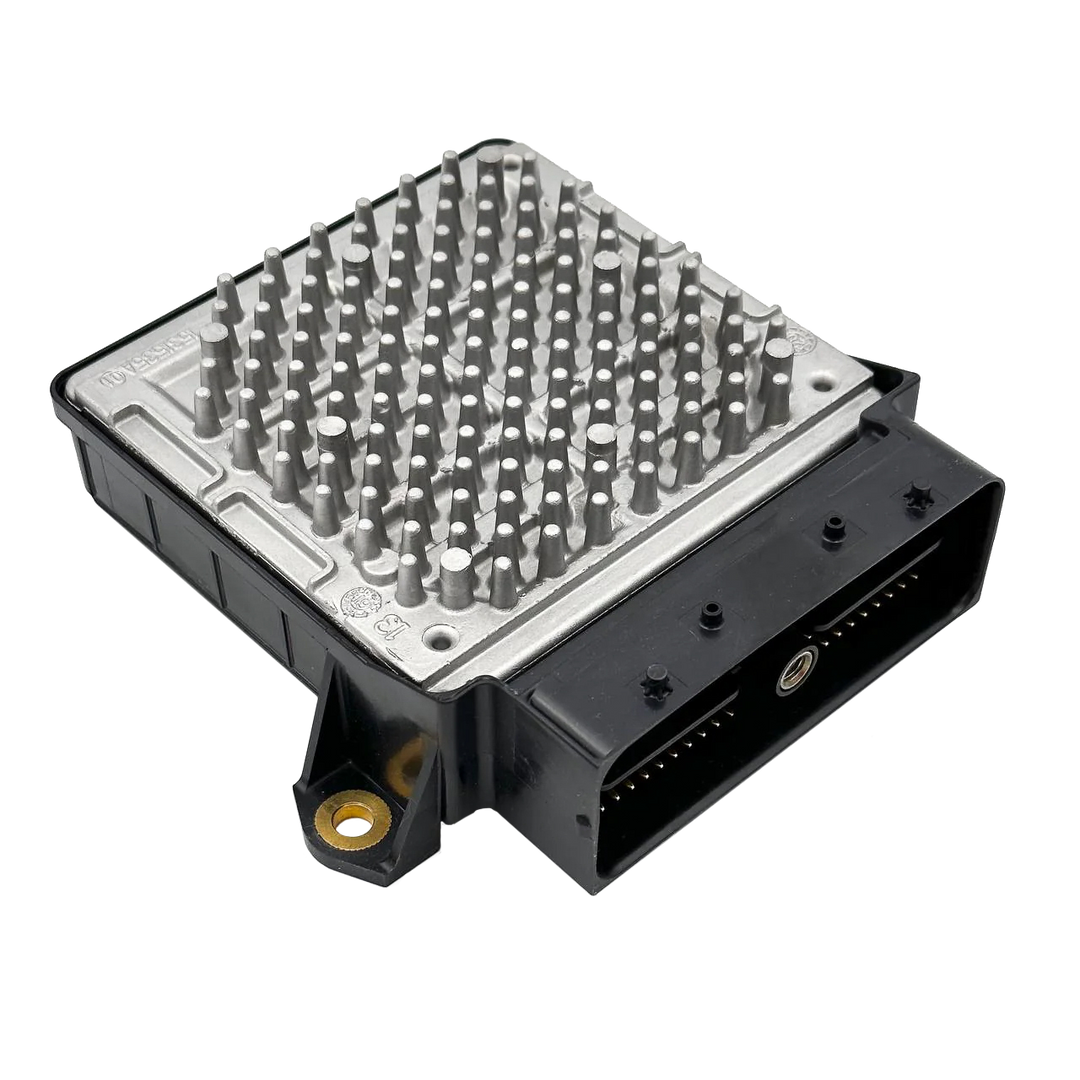

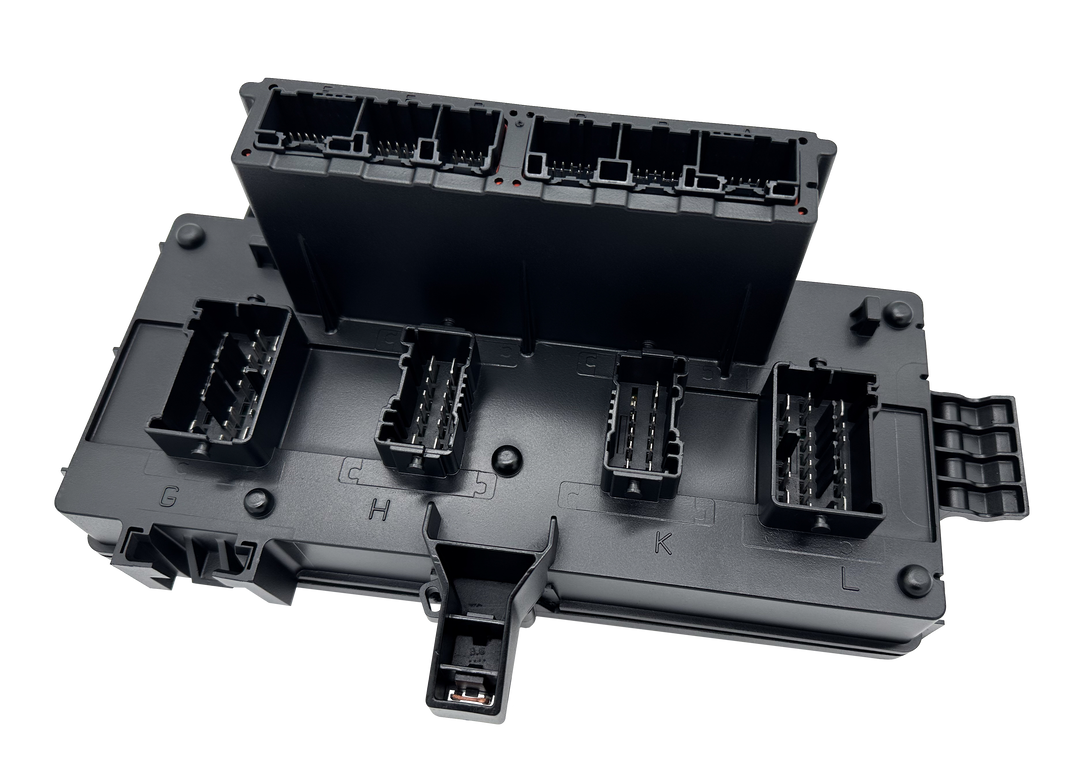

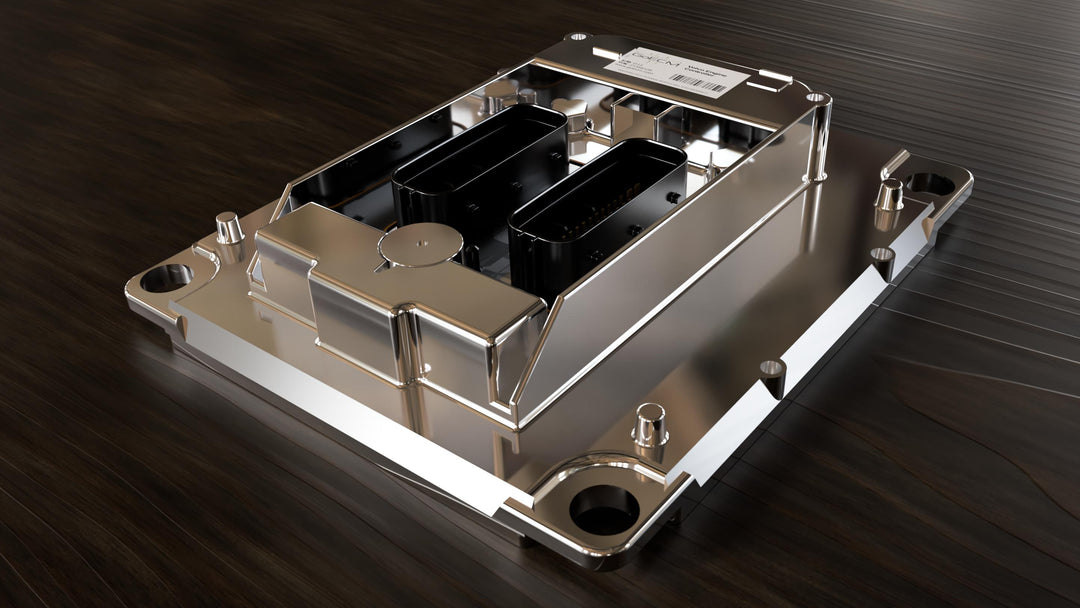

Our commitment is to give you the highest quality product and service the industry has to offer. Our control modules not only meet but exceed OEM specifications. All of our control modules are tested through rigorous assessments to ensure long-lasting reliability and guaranteed for life.

Shop ECM

View all

Services

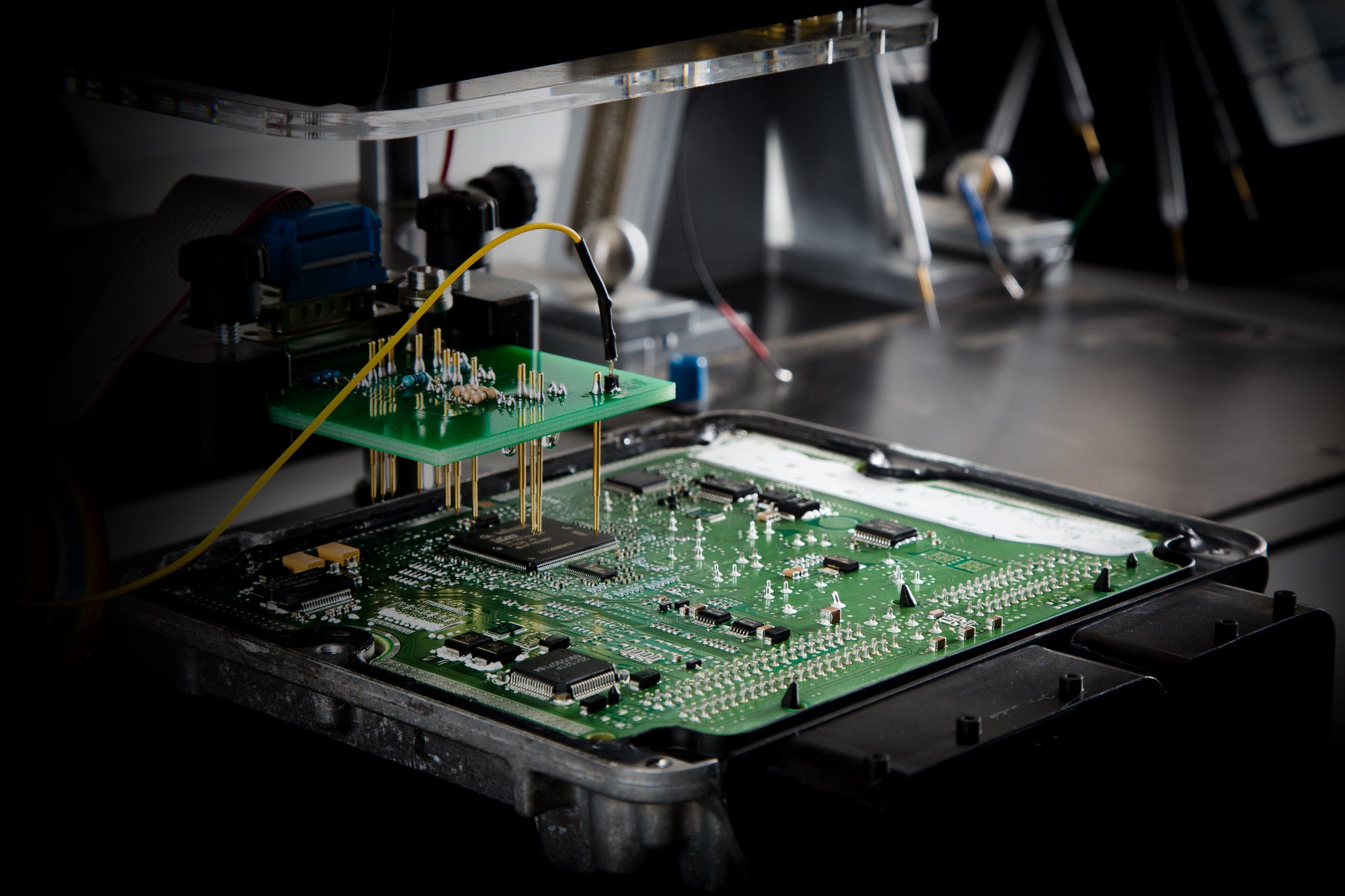

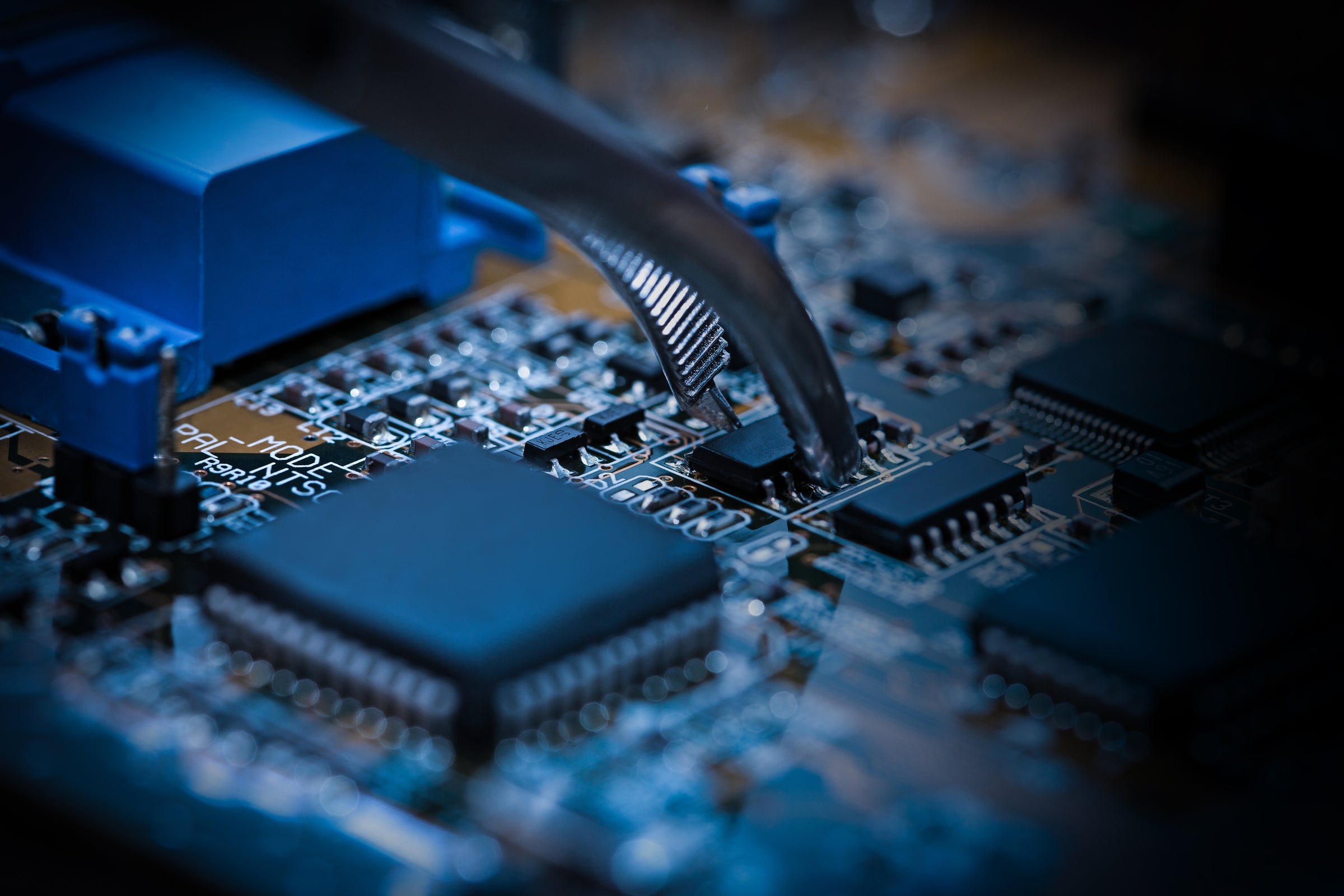

Repair & Diagnostics

We offer testing, diagnostic, and repair services for customer-owned control modules. We will completely disassemble, assess, and remedy problems found with your module. This service is designed as a cost-effective alternative for purchasing exchange modules. You will receive the same quality, reliability and durability as a new part with less cost.

From the journal

View all

GoECM Retailer Opportunities

GoECM is now introducing special pricing and services to our commercial customers. We are offering wholesale distribution of remanufactured control modules to qualified retailers. Call for more information.